Rystad's production enhancement services are not limited to providing chemicals; they also offer an integrated solution covering diagnosis, design, construction, and evaluation.

I. Production Enhancement Technology Matrix

(1) Reservoir geomechanical assessment

The geostress field is analyzed by using logging data and core experiments to accurately predict the direction of fracture extension.

Identify natural fracture zones and geological weak areas, and optimize the fracturing design to avoid penetrating the water layer or triggering earthquakes.

(2) Optimal design of hydraulic fracturing

Personalized design: Based on geological models and stress fields, optimize perforation schemes, pumping procedures (the proportion and volume of pre-fluid, sand-carrying fluid, and replacement fluid), and proppant placement profiles.

Fluid selection: We offer a variety of fracturing fluid systems such as sliding water, linear gel, and cross-linked gel, and recommend corresponding additives like drag reducers, discharge AIDS, and anti-swelling agents.

Proppant selection: From conventional quartz sand to medium and high-strength ceramsite, we provide customers with the best proppant solutions based on closing pressure and economy.

(3) Acidification stimulation service

Matrix acidification: It is used to remove pollution near the wellbore, adopting formulas such as soil acid and organic acid optimized based on core flow experiments.

Acid fracturing: In carbonate rock reservoirs, flow diversion fractures are created, and advanced technologies such as viscous fingering and self-redirecting acid are adopted to achieve uniform deep acid distribution.

(4) Increase production in the later stage of production

Water blocking and profile control: For high-water-cut old oil fields, we provide gel, granular and other blocking agents to seal the high-permeability water flow channels and improve the displacement efficiency.

Wellbore treatment: We offer mechanical and chemical wax removal and scale removal services to restore the flow capacity of the wellbore.

Ii. Digital Transformation

(1) By using the Fracturing Real-time Optimization Center (FROC), the pumping program is adjusted in real time during the construction process based on data such as wellhead pressure and microseismic conditions to ensure the optimal fracturing effect.

(2) Apply the production data analysis platform to compare the production curves before and after the production increase measures, quantitatively evaluate the effect of the measures (such as net present value NPV, payback period, etc.), and provide decision support for subsequent Wells.

PETRONOC offers an integrated solution for acid pressure completion throughout the entire process, focusing on the stimulation and transformation of carbonate and sandstone reservoirs. Our services integrate international advanced technologies with local operation experience, which can increase the production of a single well by 50% to 300%.

I. Core Technology System

Intelligent acid system

• PN-ACID series retarding acids (Temperature resistance 160 ° C /320 ° F)

Self-directed acid (VDA) enables the homogenization modification of non-uniform reservoirs

• Nanoscale acid-rock reaction inhibitor (slows down reaction rate by 40%)

Crack monitoring technology

• Microseismic monitoring (positioning accuracy ±5m)

Real-time inversion of temperature fields in distributed optical fibers (DTS/DAS)

Tracer monitoring assesses the contribution rate of each layer segment

Numerical simulation platform

• FracProPT 3D crack propagation simulation

• Geomechanical modeling (in-situ stress field analysis accuracy over 90%)

Ii. Specialized Craftsmanship

Process type | Applicable conditions | Production increase effect | Typical cases |

Multi-stage alternating acid pressing | Thick-layer heterogeneous reservoirs | Output has increased by 2 to 5 times | The Khurais oilfield in Saudi Arabia |

Closed acidification | Natural fractured strata | The diversion capacity has been increased by 8 times | The Mabrouk oilfield in Oman |

Acid pressing - gravel filling | The demand for sand control of loose sandstone | The overall increase in production was 180% | The Rumaila oilfield in Iraq |

Ultra-deep well acid pressure | Well depth > 6000 meters, temperature > 150℃ | The construction success rate is 100% | Bab oil Field in the United Arab Emirates |

Iii. Quality Control System

Material control

The purity of the main agent of the acid solution is ≥99.5%

The additive has been certified by ISO 13503

On-site QC testing (pH value, viscosity, corrosion inhibition rate)

Construction standards

The error of the pump injection program is less than ±2%

• Test the pipeline pressure to 1.5 times the working pressure

HSE management complies with OSHA standards

Effect evaluation

• Pressure drop analysis (to obtain the fracture's flow conductivity)

Production logging (PLT) quantifies the contributions of each layer

• 3-month follow-up parameter adjustment service

Iv. Typical Operation Procedures

Reservoir diagnosis stage (3-5 days)

Core tests (acid dissolution rate, stress sensitivity)

Secondary interpretation of logging data

• Small-scale Test Fracturing (DFIT

Scheme design stage (2-3 days)

• Preferred type of acid solution

• Construction scale simulation

• Economic assessment (ROI prediction)

On-site implementation stage (1-3 days)

• Wellbore preparation (well flushing, pipe scraping)

• Acid solution mixing (real-time density monitoring)

• Graded pump injection (including pre-liquid/replacement liquid)

Return exhaust management stage (5-7 days)

• Pressure control and return exhaust (0.5-1.0MPa/d reduction)

Residual acid treatment (neutralization to pH=6-8)

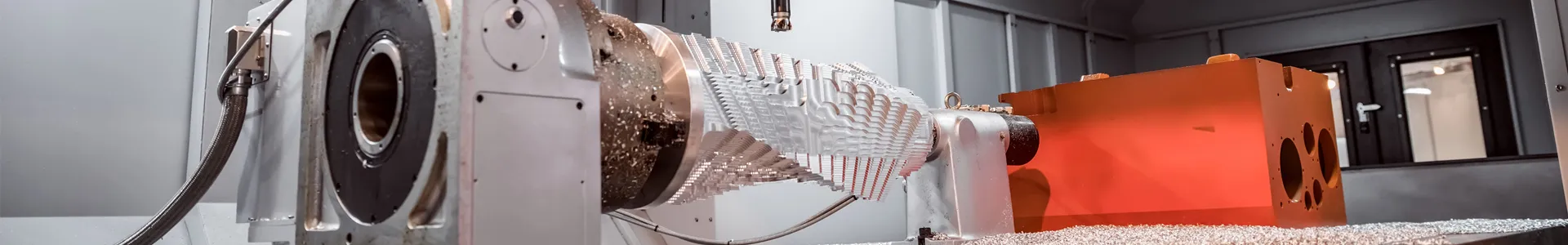

V. Equipment List

• 2000-type fracturing pump truck (Working pressure 103MPa)

• Continuous mixing device (liquid preparation accuracy ±0.5%)

• High-pressure manifold system (6"-10kpsi grades)

• Downhole memory pressure gauge (temperature resistance 175℃)

Vi. Service Area

Covering the major carbonate oil fields in the Middle East:

• Arab-D reservoir in Saudi Arabia

• Thamama Group from the United Arab Emirates

The Iraqi Mishrif team

• Oman Shuaiba Group